Nissan has unveiled its all-new LEAF electric car which will be produced in Sunderland.

It is the first model to be launched under Nissan’s EV36Zero blueprint for the future of EV production and will be built in the North East by the plant’s team of 6,000 people.

LEAF has been engineered for European customers at Nissan’s UK research and development centre, NTCE, in Cranfield, Bedfordshire.

It will be powered by batteries from AESC – Britain’s newest gigafactory – which is situated next to the Nissan plant.

The next-generation Nissan Qashqai e-POWER will arrive in the coming months at the same plant, followed next year by an all-new fully electric Juke.

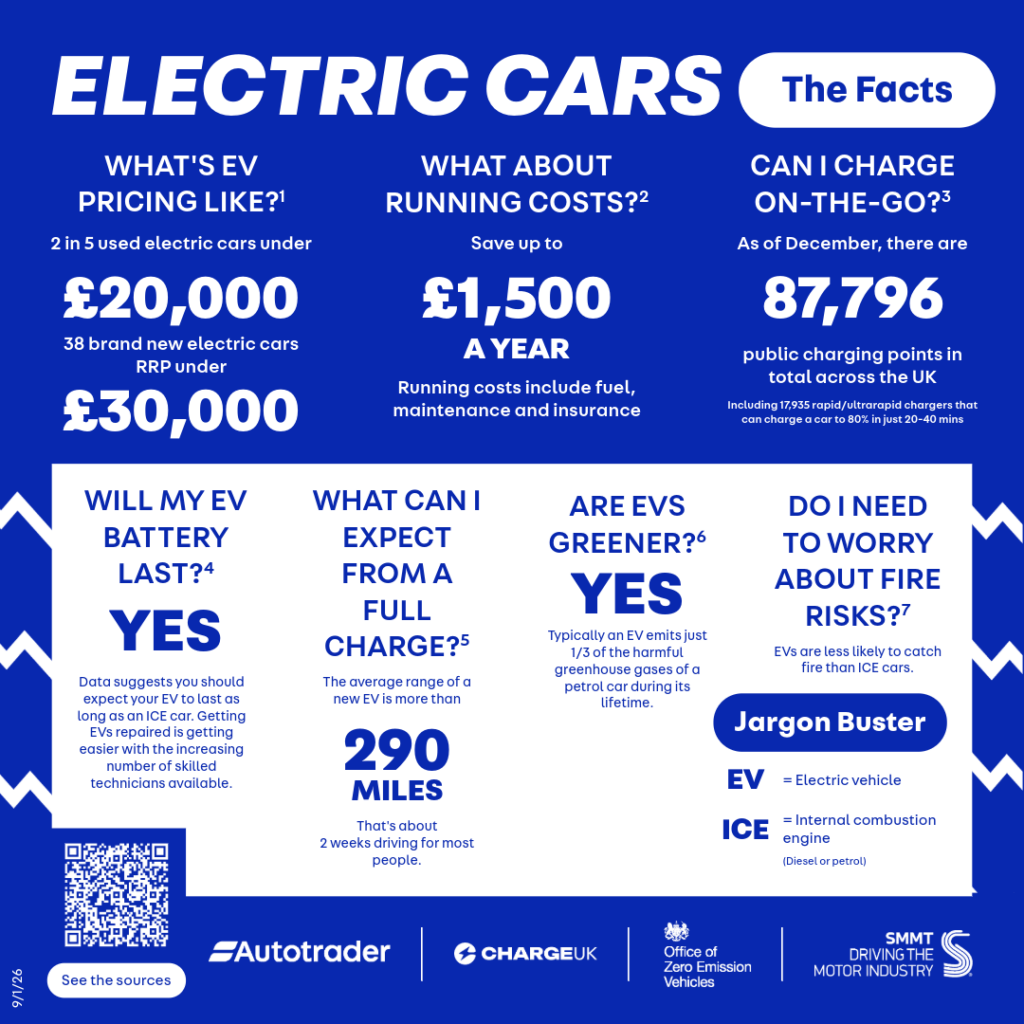

The new LEAF will be able to travel up to 375 miles on a single charge and will be available for customers to order later this year.

A new fully-electric Micra, designed in London, will go on sale later this year, and Nissan will also launch a smaller city car in 2026 in order for the brand to have a full range of electric vehicles for all customers.

Alan Johnson, Senior Vice President of Manufacturing & Supply Chain Management at Nissan Motor Manufacturing, said:

“It’s with immense pride that we unveil the third-generation of our pioneering electric LEAF, twelve years after we brought EV and battery manufacturing to the UK.

“It’s a testament to the skill of our world-class team that we can bring into mass production a vehicle with such advanced technology and aerodynamic design. We can’t wait to see it on the roads.”

James Taylor, managing director of Nissan GB, said:

“We’re really excited about the launch of the all-new LEAF later this year. It builds on the success of the previous two generations, which have found homes with more than 70,000 UK customers.

“LEAF is a pioneering electric vehicle that has encouraged thousands to make the switch to electric motoring – and best of all, it’s built here in Britain.”

Image courtesy of Nissan