Foster Contracting have estimated that values ranging from 29% to 93% can be achieved in carbon reduction, along with significant cost savings when using geosynthetic interlayers to extend the life of a pavement.

In April 2023, PYE Management Ltd produced a document for the Road Surface Treatments Association (RSTA) entitled “Carbon Emissions for Road Surface and Other Maintenance Treatments for Asset Management Purposes”. It states that road surface treatments are methods or materials for extending the lifetime of road pavements, delaying the need for major maintenance or rehabilitation.

Using data derived from this, Foster have put together their information document ‘Carbon and Cost Benefits of FCL’s Geosynthetic Interlayers’, which shows both the potential for immediate, and whole life carbon and cost savings in using their geosynthetic interlayers.

Foster estimate that values ranging from 29% to 93% can be achieved in net carbon reduction, along with a net cost reduction between £13/sq.m. and £38/sq.m. These claims are backed up in the document which outlines the background behind these values and offers worked examples for six scenarios.

The first three scenarios focus on the use of FCL’s interlayer service in conjunction with a surface course layer, with the last three scenarios assessing the impacts of using their interlayer service under a binder course.

Both the RSTA and PYE Management support the findings in the ‘FCL Carbon and Cost Benefits Information Document’.

Craig Andrews, Technical Director for Foster Contracting, said:

“Geosynthetics can optimise pavement performance by preventing premature failure and extending pavement life to achieve whole life carbon and cost benefits.

“With councils facing increased budget constraints, they need to think about how they can be more sustainable in their approach to maintenance of their pavements, without breaking the bank.

“The statistics highlighted in our Carbon and Cost Benefits Information Document, which have been verified by the Road Surface Treatments Association and PYE Management, show the level of carbon and cost benefits that can be made from using our geosynthetic interlayers.

“What is most impressive, is that the figures presented in our information document are net values; they have already accounted for the carbon and costs associated with the manufacture, supply, haulage and installation of our interlayer products.”

For all six scenarios, Foster account for the lifecycle from ‘cradle to lay’, which gives values for an installed pavement. This caters for the process through to practical completion, as stipulated in BS EN 15804 (modules A1 to A5).

Cracking in asphalt pavements is recognised as one of the biggest problems faced by local highway authorities, with the cracks being the precursor to pothole development. Geosynthetic interlayers are a proven approach for maintaining or extending the life of pavements.

One of the best treatments, used extensively over the past 30 years in the UK, is a geosynthetic interlayer which is installed within the bound layers, to intercept the path of crack propagation by reinforcing the bound layers, dissipating / absorbing stress, and creating a moisture barrier in the upper pavement.

Paul Boss, CEO of the Road Surface Treatments Association, said:

“FCL’s Information Document successfully demonstrates the carbon and cost benefits of using geosynthetic interlayers in road maintenance construction, as part of the implementation of a sustainable and efficient asset management strategy.”

Emma Pye, Founder and Director of PYE Management, said:

“Foster Contracting have used RSTA’s Carbon Emissions Report exactly as it was intended, to take the base carbon information per m2 to produce detailed calculations for low carbon strategies. Having this information enables customers to make both cost and sustainability decisions when planning highways works, a key tool that is very much needed in the current climate.”

Foster Contracting supply and lay geosynthetic interlayers for crack reduction in asphalt surfaces, runway rubber and paint removal, surface retexturing and other specialist surface treatments.

A copy of FCL’s Carbon and Cost Benefits document can be requested via email at technical@fcl.uk

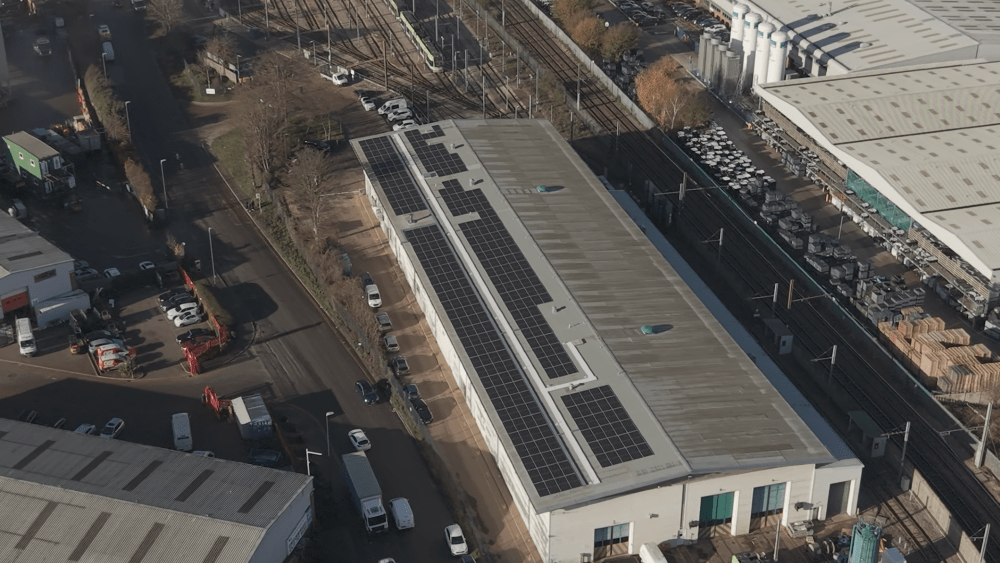

Image courtesy of Foster Contracting.