New government funding of £211 million will be spent on battery research and innovation.

The record funding uplift will be delivered through the Faraday Battery Challenge, which began in 2017 and supports world-class scientific technology development and manufacturing scale-up capability for batteries in the UK. It will help to seize on opportunities for private investment and economic growth in industries where powerful, fast charging batteries will be essential – such as domestic energy storage and electric vehicles.

The funding, from last year’s settlement, will be delivered between 2022 and 2025 by UK Research and Innovation (UKRI) with support from the Faraday Institution, Innovate UK and the UK Battery Industrialisation Centre (UKBIC).

It will help the sector deliver 100,000 jobs in battery gigafactories and the battery supply chain by 2040. Supporting the scale-up of these technologies and unlocking further private investment supports the sustainable growth of the economy, which will boost tax revenues and put public services on a more secure footing for the longer term, helping improve life for people across the UK.

Speaking on a visit to the £130 million UKBIC, which is the UK’s centre of excellence in battery manufacturing, Business Secretary Jacob Rees-Mogg said: “Safe and powerful batteries are central to our plans to grow the industries of the future. From our world leading renewables industry, to our growing electric vehicle sector, secure supplies of batteries are key to delivering jobs and prosperity.

“The Faraday Battery Challenge has brought the UK’s greatest minds and best facilities together to develop the innovations that will help us achieve this goal. The work it has done since 2017 has laid the groundwork for our future economic success and I am pleased to confirm this work will continue, supported by record funding.”

The Faraday Battery Challenge combines:

- Research and capability development to reduce battery weight and cost, increase energy and power, and ensure reliability and recyclability;

- Collaborative business-led innovation in the UK battery sector, development of the wider network and skills needed to manufacture batteries through Innovate UK; and

- Manufacturing scale-up & skills development at the UKBIC the national battery manufacturing development facility.

The Challenge has supported over 140 organisations working across the UK, attracting over £400 million in further private sector investment. It has enabled the Faraday Institution, the UK’s independent battery research body, to unite 500 researchers across more than 25 universities to improve current and develop future battery technologies.

Faraday Battery Challenge Director Tony Harper said: “This new funding allows us to strengthen the foundation we’ve created by consolidating and building on the UK’s position to become a battery science superpower. We now have an opportunity to ensure that our national industrialisation infrastructure remains world leading in this fast-evolving critical net zero technology.”

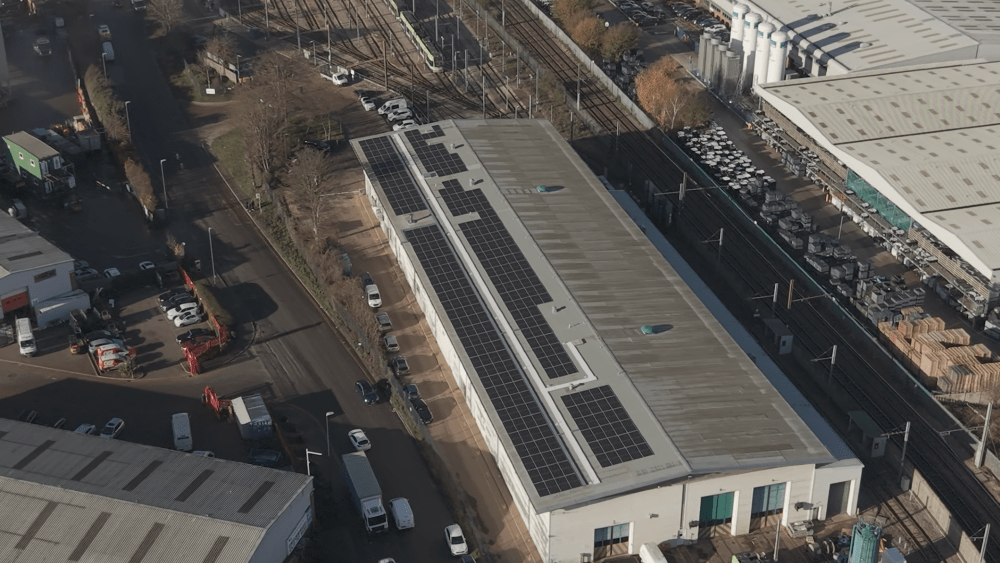

With the support of the Challenge, the £130 million UKBIC in Coventry opened three years ahead of its nearest European competition. The Centre provides the link between battery research and successful mass production. So far the Challenge has UK battery developers working on more than 80 research and innovation projects, to successfully scale their products to market.

Felicity Buchan, Exchequer Secretary to the Treasury, said: “The battery industry will play a pivotal role in the growth of our future economy. That’s why it’s so important that we are making this record investment in cutting-edge research, supporting businesses to become more innovative and productive, and creating high-skill, high-wage jobs across the UK.”

UKBIC Managing Director Jeff Pratt said: “I am delighted with this announcement which demonstrates the government’s sustained commitment to supporting the development of advanced battery technologies across the UK. Since the Faraday Battery Challenge was launched in 2017, we have seen rapid change in the battery industry as it develops increased capacity across Europe; and this will continue over the coming decade.

“For UKBIC, this additional funding will ensure that we retain our leading-edge manufacturing capability for the UK and can continue to support our industry in the next few years as novel chemistries and formats scale towards volume production.”

UKRI Chief Executive Professor Dame Ottoline Leyser said: “Advanced battery technology will play a central role in our lives and the economy, reducing our reliance on fossil fuels, creating new jobs and opening up new opportunities.

“The Faraday Battery Challenge is at the forefront of the clean technology revolution, catalysing collaboration and innovation that will benefit society. This exciting work and the further investment announced today underlines the ways in which research and innovation can help to create a sustainable future while driving economic growth.”

Faraday Institution CEO Professor Pam Thomas said: “A thriving British battery industry will be grounded on a strong UK-based research and innovation ecosystem, developing batteries fit for purpose, lower cost, safer and fully recyclable. The 500-strong Faraday Institution research community is a cornerstone of this national initiative.

“I am grateful for this announcement, which will allow the Faraday Institution to do what is needed to realise the full potential of energy storage technologies and to position the UK as a globally recognised beacon for battery research.”

Along with the Challenge, the UK government is helping to deliver a world leading electric vehicle industry for the UK through the Automotive Transformation Fund (ATF). Through the ATF the UK has secured major investments in battery production, including Envision AESC expanding their existing plant in Sunderland.

A further £4 million is also being announced through UKRI’s Driving the Electric Revolution Challenge to support skills, talent and training across Power Electronics, Machines and Drives (PEMD) manufacturing and supply chains. PEMD components are the parts that make things ‘go’, from cars to hairdryers, underpinning a wide range of high-value industries.

Image courtesy of Shutterstock.