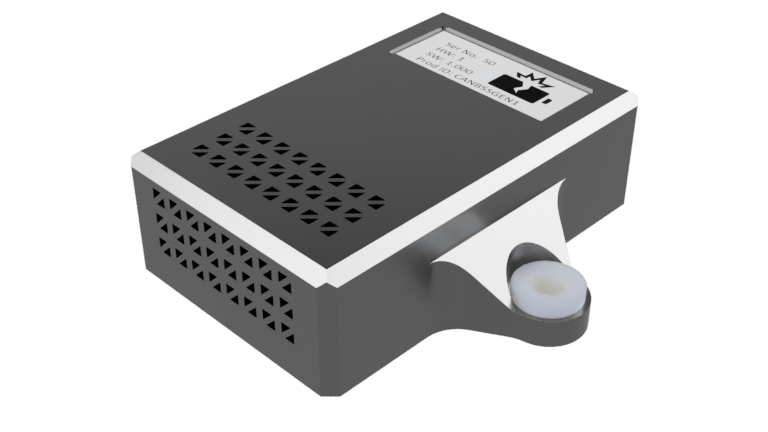

Metis Engineering has revealed the production version of their Battery Safety Sensor, a CAN (Controller Area Network) based sensor designed to detect cell venting, an early sign of catastrophic Electric Vehicle (EV) battery failure.

The sensor would be mounted inside an EV battery pack where it ‘sniffs’ the air to detect a lithium-ion battery cell venting.

The Sensor is designed to pick up a range of environmental parameters, including hydrogen, Volatile Organic Compounds (VOCs), pressure change, humidity, dew point and absolute water content.

This data can be used to crosscheck with other inputs, such as cell temperatures, to check for cell venting; the sensor then relays the data over a configurable CAN interface to a control unit such as the vehicle’s ECU to cut the load from that part of the battery pack, thus preventing thermal runaway.

There are several stages to a cell going into thermal runaway. First, there is an increase in temperature, often caused when a battery is overworked, has a manufacturing fault, or is aged.

The rise in temperature causes the pressure inside the battery cell to rise. Eventually that pressure, if high enough, causes venting from the sealed battery cell, and if load is not removed from this cell then a thermal runaway can occur.

The ultra-sensitive pressure sensor can detect small increases in pressure inside a battery case caused by venting. This spike in pressure can be cross-checked with the VOC and humidity sensor to avoid false-positive warnings.

If a battery is driven to failure after venting, it can catch fire in a self-oxidising reaction, which will most likely result in a runaway reaction, setting off the cells around it, and causing the loss of the vehicle.

Metis Engineering Managing Director, Joe Holdsworth, said: “It will enable EVs to be safer than ever before. The technology packed into the sensor module makes it a unique and affordable addition to every battery pack. An electric car might have two sensors, whilst an electric bus would have 6 – 8, depending on the number of battery packs they distribute around the vehicle and the internal air volume of the packs.

“Being able to life a battery pack right from manufacturing to fitting into a vehicle is possible thanks to the sensor’s accelerometer. You’ll know if the pack was dropped in transit or if once fitted to a vehicle, what loadings it experienced during a collision. EV insurers will be very keen to ascertain if the high-value battery packs need to be serviced or written off.”

The sensor also includes an accelerometer so it can monitor shock loads and impact duration, of up to 24G, that the battery pack may experience. The sensor can even be fitted to the battery pack during manufacture, and monitor the pack throughout transportation from factory to fitting within the EV.

Once fitted, the sensor will continue to monitor the pack’s health. Should the EV be involved in a collision, the sensor will show whether the pack experienced loadings above safe levels, and for what duration.

This could inform the decisions as to whether the battery pack requires a service, re-lifeing for domestic or industrial use, or be sent for recycling and any subsequent insurance claims.

Image: courtesy Metis Engineering